Liquid Manufacturing and Repack

Enhancing Facility Efficiency with Innovative Automation Solutions

Project: Landus, Boone, Iowa

OVERVIEW

Landus constructed a state-of-the-art three-bay facility in Boone, Iowa, for fertilizer, chemical manufacturing, and repack. Their Kahler Automation system features two access-controlled bays to dispense product simultaneously and be unstaffed 24/7 so customers can fill orders anytime. Every product is weighed during dispensing, increasing reliability while reducing maintenance.

WHAT THEY NEEDED

Landus needed a state-of-the-art fertilizer, chemical manufacturing, and repack facility. To be competitive in the future, the company needed to consolidate numerous local operations into one primary facility. The company wanted the ability to produce products that work on Iowa farms and create value for their growers. Landus needed a streamlined facility to service its customers of tomorrow by offering direct ship distribution options to farmers and suppliers across the Midwest. Accomplishing all of these things would require speed, reliability, and efficiencies.

WHAT WE DESIGNED

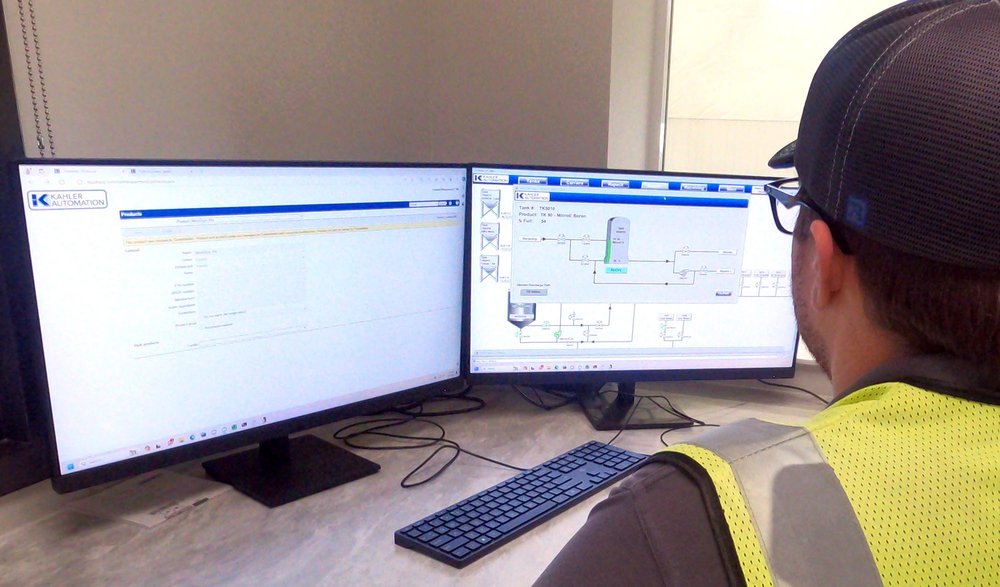

Landus constructed a new three-bay fertilizer and chemical facility in Boone, Iowa. The system features two access-controlled bays to dispense product simultaneously and be unstaffed 24/7 with a bay to receive product. Localized control design simplifies installation and maintenance, ensuring connectivity throughout. The system is designed to provide operational efficiency to ensure that current and future customers get what they need accurately and quickly. Landus connected all of their locations that use Kahler software with Constellation, giving them complete site visibility for easier overall analysis and business management. Orders are communicated through a single interface, eliminating the need to manage integrations at individual sites. Order interfaces are managed in the cloud, reducing network vulnerability.

SPECS AT A GLANCE

Type of Business: Retail

Products Offered: Liquid fertilizer and crop protection chemicals

Total Square Feet: 66,000

Type of Construction: Steel building

Receive Product Via: Truck

LIQUID FERTILIZER AND CROP PROTECTION

Indoor Liquid Fertilizer Storage: 210,000 gallons in seven tanks

Bulk Chemical Storage: 350,000 gallons in 36 tanks

Type of Fertilizer Stored: Starter, UAN, AMS, ATS

Diked: Yes

Mixing: Yes

Type of Containment System: Concrete

Load-Out Capacity: Up to 450 gpm

Number of Trucks per Hour: 12

Number of Operators Required: 1 staffed, 0 for unstaffed

Control Automation: Kahler Automation

Scott Ahrenholtz

WHAT THEY HAD TO SAY

Scott Ahrenholtz, AcreEdge Product Agronomist, Landus

“Kahler has been very strategic for us in order to service the farmer of tomorrow with speed and reliability, create billing efficiencies, and really operate more like a well-run business. We were looking to be able to cross-train, streamline employees; having a group of employees that already know what they’re doing and how to use the software [allow us to] pull human capital from other locations to come in here and operate the facility at different times. Kahler’s committed to continuing to be the leader in automation in the agriculture space.”

Tim Glienke

WHAT WE HAD TO SAY

Tim Glienke, Regional Account Manager, Kahler Automation

“The system we created with Landus not only delivers speed but, since every product is weighed during dispensing, it has better reliability with less maintenance. Products can be received and dispensed 24/7 for optimal customer convenience. Source destination is used to receive product unstaffed to ensure products are routed correctly, along with real-time inventory adjustment based on the product amounts. The system is designed with the operator in mind to maximize efficiency and ease of use.”