Your Partner in Liquid Fertilizer Automation.

Liquid fertilizer automation systems that optimize loadout efficiency, traffic control, and facility performance.

EFFICIENCY

ACCURACY

PRODUCTIVITY

OPTIMIZATION

EASE OF USE

Your complete liquid fertilizer automation solutions.

WE ARE KAHLER AUTOMATION

One Platform. Complete Control.

FLEXCOMMAND® brings your liquid operations together in a single, intuitive interface. Centralized settings, real-time visibility, and intelligent automation give your team better control over blending, loadout, inventory, and reporting — across one facility or many.

Built for today’s high-demand environment. Designed to scale with you.

From receiving to loadout, Kahler Automation delivers integrated liquid automation solutions that ensure blending precision, real-time inventory visibility, and total operational control.

Accuracy You Can Trust. Performance That Improves Over Time.

Achieve precise dispensing and blending with a full range of advanced measurement technologies, including:

- Mass flow meters

- Volumetric flow meters

- Platform and truck scales

- Chemical weigh tanks

Our intelligent software continually refines accuracy while creative PLC programming and timed purge cycles prevent cross-contamination — protecting product purity and customer confidence.

Handle up to 100 products with precision.

Blend smarter. Load faster. Waste less.

Real-Time Inventory. Anywhere.

Know exactly what’s in your tanks — at every site.

Track product in and out with automated inventory updates during receiving and loadout. Monitor tank levels using multiple sensor types, set alarms, and access system data from any smart device.

Whether you manage one facility or multiple locations, your inventory data stays accurate, reliable, and accessible.

Staffed & Unstaffed Receiving

Simplified Product Receiving

Capture inventory automatically during receiving. Approved drivers or operations staff can initiate system information before or during unloading —streamlining intake while maintaining accuracy and security.

Remote visibility ensures you stay informed without being on site.

24/7 Unstaffed Loadout

Secure. Self-Serve. Always Operational.

Enable safe, secure, around-the-clock loadout with a customizable touchscreen interface.

Approved drivers can:

- Select products

- Enter destinations

- Track load status

- Access transaction history

Administrators can manage users, permissions, configurations, and reporting through a built-in IP web interface, with full transactional memory and product data tracking.

Operate continuously. Reduce labor dependency. Increase throughput.

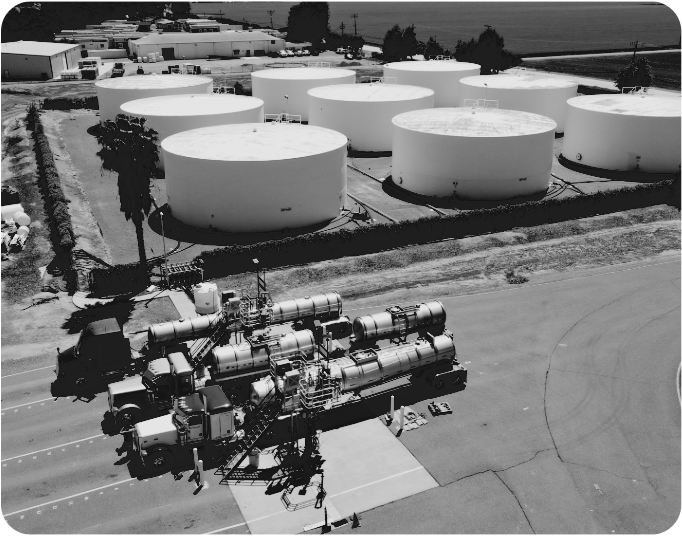

Pumping Skid Systems

Turnkey Automation. Ready When You Are.

Our pre-engineered pumping skid systems reduce installation time and accelerate startup.

- Installation-ready design

- Fast, simplified connections

- Custom configuration options

- NTEP - approved for legal trade

Get up and running faster — without compromising precision.

Barge & Rail Control Systems

Controlled Receiving. Captured Data.

Streamline rail car and barge receiving with automated inventory capture and simplified loadout processes.

- Remote data management via a web browser

- Visual loading indicators

- Real-time receiving documentation

Improve traceability, reporting, and operational efficiency from dock to tank.

The Technology Behind

High-Performing Facilities

-

Automation Control Software

One Platform. Total Facility Visibility.

Bring all your locations together under one powerful control system interface.

Our automation software centralizes equipment control, business data, inventory tracking, and reporting into a single streamlined platform. Empower your team with real-time insights, simplified data management, and full operational visibility across your enterprise.

- Truck Traffic Control

- Motor Control Centers

A smarter way to automate liquid fertilizer operations

From precision metering and blending to full-facility integration, Kahler Automation delivers proven automation solutions trusted

by hundreds of operations across North America.

.png?width=400&height=74&name=FLEXCOMMAND_TAG_RGB_stroke-CLEAR_nomark%20(1).png)